Overhauser base station magnetometer SmartMag

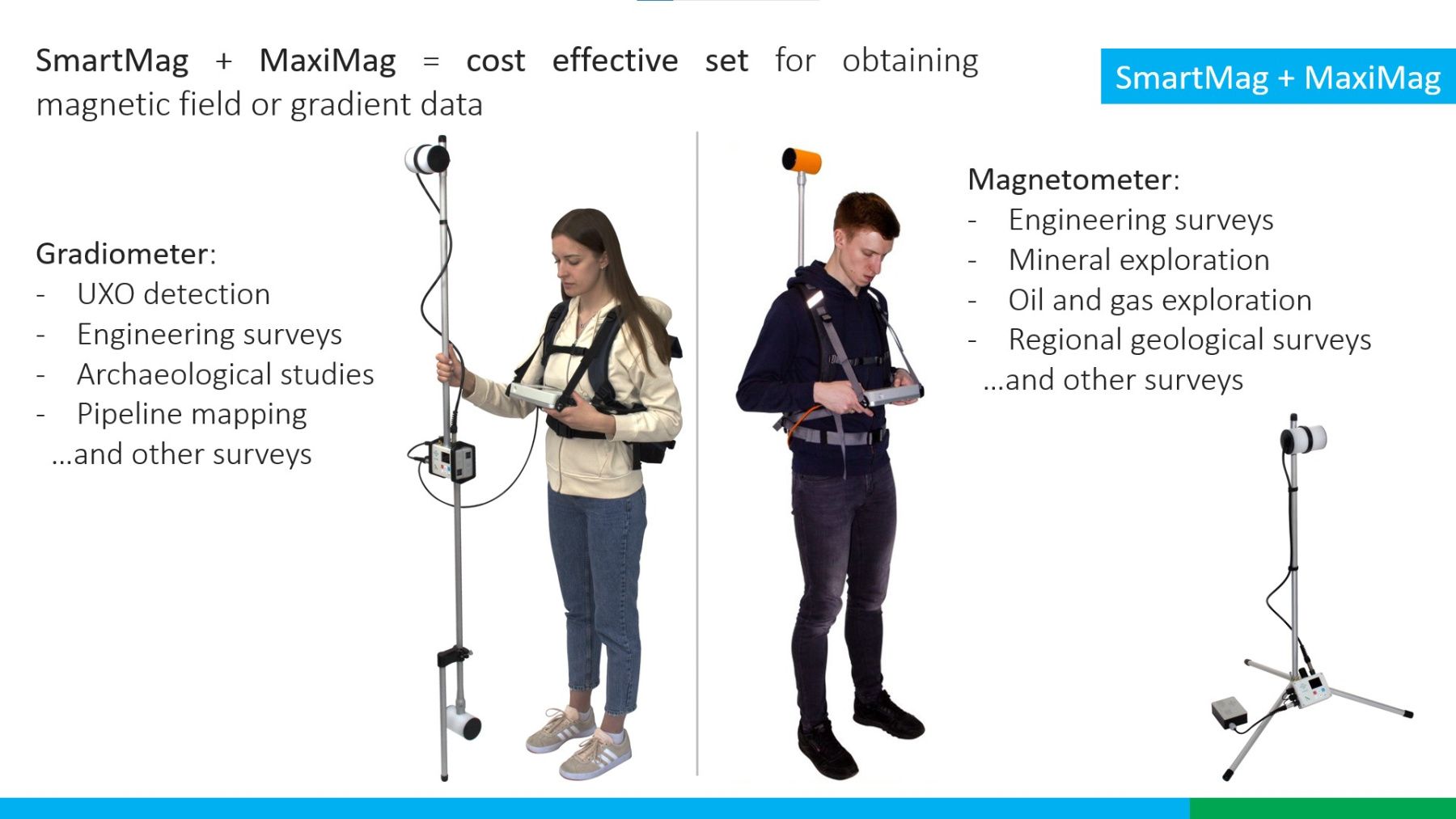

SmartMag – the World's most advanced and portable magnetometer based on the Overhauser effect. The complete ready to use set with all necessary accessories and battery fits in a carry-on size case and weighs only 7.5 kg. SmartMag can be used as an observatory magnetometer, base station, as part of a multi-sensor gradiometer, or even as a GNSS base and rover with centimeter accuracy in PPK mode. It is fully compatible with MaxiMag console and can be applied for any type of ground magnetic surveys.

Easy-to-use console

The console enables easy configuration of operating modes, visual control of measured values and viewing of stored data from the built-in microSD card. Downloading data is performed via USB to a PC or smartphone. It is also possible to broadcast data via RS-232 or CAN ports in real time mode. The console is equipped with an OLED display (-40 ÷ +60 °C), built-in multi-band GNSS receiver with RAW GNSS data collection, and backlit keypad.

Magnetometer for magnetic observatories

High sensitivity, sampling rate, and accuracy (less than 0.1 nT) makes SmartMag one of the best magnetometers for magnetic observatories. Real-time data broadcasting realized via CAN FD or RS-232 connection. With the optional CAN-Ethernet interface unit SmartMag can be connected directly to network. The digital CAN FD cable can be up to several kilometers long. The device is supplied with the SmartManager software that has all the necessary functionality to perform measurements in the INTERMAGNET network of magnetic observatories.

Magnetometer parts

The magnetometer package contains on the one hand a minimum number of unified parts to ease assembly and use, and on the other hand all the necessary components, so that you do not have to buy additional cables, a battery, or GNSS receiver without which you will not be able to work.

Every magnetometer we ship is ready to use in its basic configuration. Options add functionality, but are not required by most users for standard operating scenarios.

Power supply

SmartMag operates over 12 hours of continuous measurements at -30°C from the battery included. At 20°C, the operating time increases to 23 hours. Continuous power supply in long term monitoring mode can be provided with a car battery, an optional low-noise power converter from 110/220VAC to 12VDC, or a solar panel.

Included Li-ion battery has the full temperature range from -40 up to +70°C and MSDS certificate for any kind of transportation.

SmartMag does not contain built-in batteries, which complicate air transportation and sooner or later fail and require complex replacement.

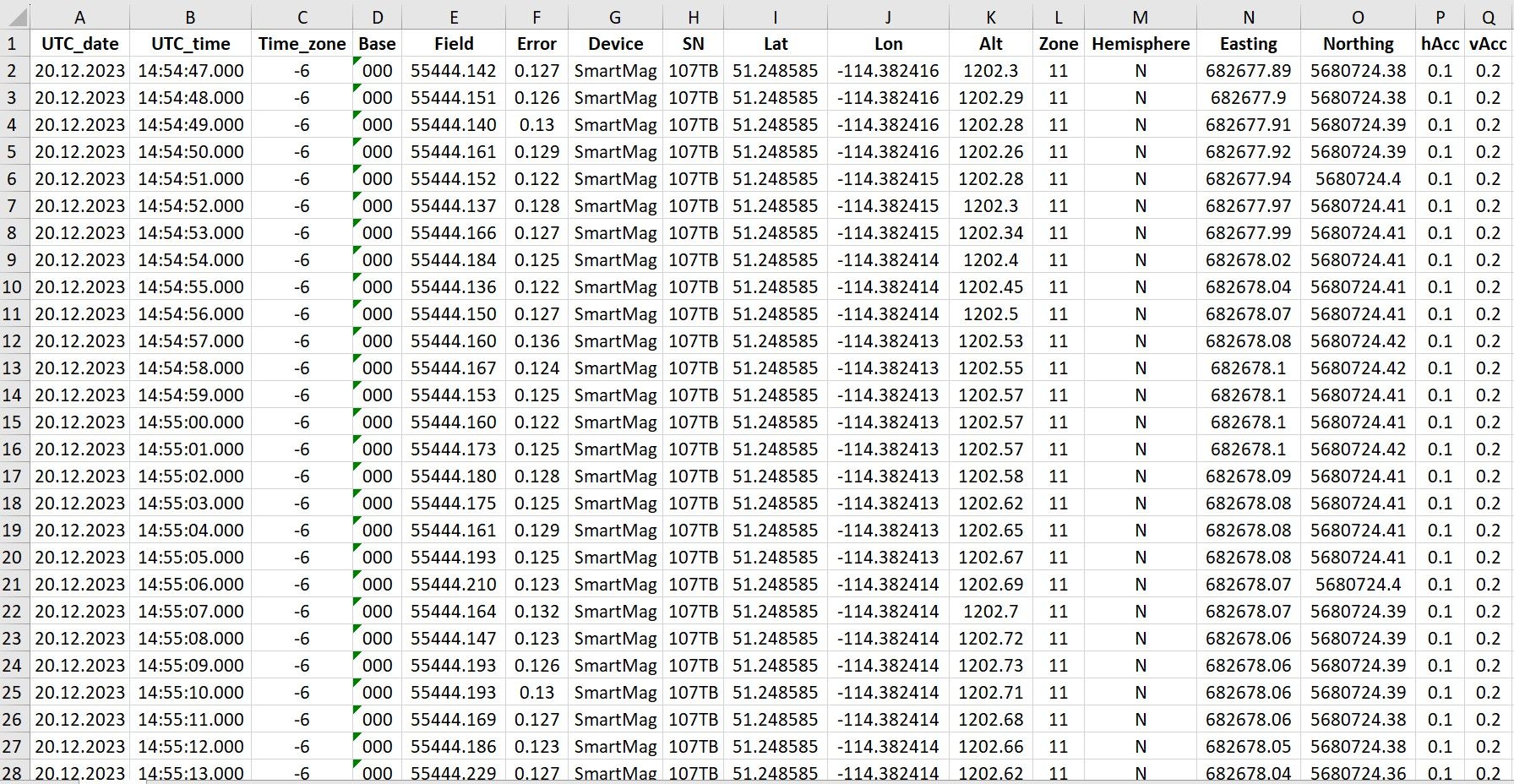

Data format

User can create project folders that can be used to divide survey sites or data collection days. All measurements are saved in a TXT file in the project folder. The file from each magnetometer has a name containing the serial number of the console, the code of the measurement mode and the number of connected sensors. The files have a homogeneous structure, i.e. each measurement in the file is a line that contains all necessary information: UTC date and time, time zone, base name, measured field, estimated error, sensor serial number, latitude and longitude in decimal degrees, altitude, UTM coordinates with automatic zone and hemisphere selection, horizontal and vertical accuracy.

Even if there are many operators working on a survey site at the same time, you will always be able to identify which instrument was used for each single measurement in the database.

Multi-sensor gradiometer

SmartMag supports the ability to link through a CAN FD interface to create a synchronized distributed network of magnetometers. This unique feature allows flexible creating of multi-sensor gradiometer with the necessary measurement base. You can connect up to 30 SmartMag’s to the a MaxiMag console or build a multi-sensor gradiometer with an almost unlimited number of sensors using CAN-Ethernet interface unit.

Metrology and noise protection - a guarantee of high accuracy

Every SmartMag is metrologically tested. We control the standard deviation of random error (noise), absolute accuracy and orientation error.

The robust algorithms allow to perform measurements at high level of industrial noise, in a city environment, or right under high-voltage powerlines.

Reliability and warranty

Our R&D specialists have extensive experience in performing geophysical surveys. We are well aware that such equipment must be reliable, and the service must be fast and convenient. We give 3 years warranty on all our magnetometers, and our technical support will promptly answer any of your questions. Our Overhauser sensors have the longest in the World lifecycle of more than 10 years. If you are still working with outdated magnetometers - take advantage of our trade-in offer and protect your projects from potential problems.

Built-in multi-band GNSS receiver with centimeter level accuracy

Time and coordinates are provided by the built-in multi-band GNSS receiver with PPK feature, that allows to achieve a centimeter level accuracy. SmartMag also has GNSS receiver mode and can be used as a GNSS base, rover or tracker without mag sensor connected during any geophysical applications. Stored RAW GNSS data could be easely converted to RINEX format.

SmartMag supports NMEA-0183 protocol and can be connected to external navigation devices via RS-232.

- Carry-on size transportation case with whole equipment setup weight 7.5 kg only

- Keyboard with backlight

- More than 12 hours of continuous operation at -30°C and 23 hours at 20°C using the battery included

- Power cable for standard lead-acid battery included

- All rods are unified - a tripod or a long pole can be assembled

- Base station with continuous measurements

- GNSS receiver mode with ability to collect RAW GNSS data for a centimeter level accuracy with base or rover modes

- Base station for ground, drone, and airborne magnetic surveys

- Magnetic observatory

- Volcanology and earthquake prediction

- Operation with MaxiMag as a part of gradiometer for any type of ground magnetic surveys

- Magnetic field measurement mode control

- Visualization and quality control of measured data

- Visualization of the calculated measurement sensitivity

- Saving daily data files

- Real-time data broadcasting via Ethernet to a PC or Internet

- Creating a synchronized distributed network of magnetometers

- Power adapter 100-240 VAC

- Backup power supply from external 12 V battery

- SmartMag console with built-in multi-band GNSS receiver

- Overhauser sensor on rod

- External GNSS antenna on rod

- Rope locking tripod hitch

- Li-ion battery 14.8V/4Ah with charger

- Non-magnetic tripod

- Console bracket

- AGM battery power cable

- USB cable

- Smart base station carry-on case

- SmartManager software

- CAN-Ethernet interface unit for connecting to PC/router

- RS-232 cable for real-time data broadcasting

- Power supply 100-240 VAC

- Additional Li-ion battery

|

Type |

Overhauser magnetometer |

|

Number of sensors |

up to 30 with MaxiMag console |

|

Dynamic range |

20 000 to 120 000 nT |

|

Absolute accuracy |

0.1 nT |

|

Sensor sensitivity |

0.021 nT/√Hz rms |

|

Resolution |

0.001 nT |

|

Gradient tolerance |

30 000 nT/m |

|

Sample rates |

0.2, 0.25, 0.5, 1 s and longer with 1 s step |

|

Sensors stability |

> 10 years |

|

Additional sensors |

IMU, compass |

|

Interfaces |

built-in: USB, RS-232, CAN FD |

|

Maximum communication cable length |

up to 6 km (CAN FD), up to 100 m (RS-232) |

|

GNSS receiver |

built-in and optional external |

|

GNSS antenna |

external |

|

GNSS signals |

GPS L1C/A and L2C; GLONASS L1OF and L2OF; Galileo E1B/C and E5b; BeiDou B1I and B2I; QZSS L1C/A, L1S and L2C. SBAS: WAAS, EGNOS, MSAS, GAGAN. |

|

Connectors |

2 × CAN FD / RS232 / 12V, USB, external GNSS antenna, Overhauser sensor |

|

Display |

160 × 128, OLED |

|

Keypad |

6 buttons with backlight |

|

Built-in memory |

up to 32 Gb (microSD) |

|

Power supply |

9.5-21 VDC, LiPo 3S/4S, Li-ion 3S/4S, LiFePo4 4S, or lead-acid battery |

|

Operating temperature |

–40 to +60 °C |

|

Battery included |

14.8 V, 4 A·h |

|

Dimensions with connectors |

Ø73×116 mm – sensor |

|

Item weight |

0.45 kg – console 1 kg – sensor on rod 0.7 - Li-ion battery |

|

Weight of a set includes console, sensor, battery, tripod, and GNSS antenna |

3.1 kg |

|

Delivery package size and weight |

55.8 × 35.5 × 19 cm, 7.5 kg |